A simple hydrophone

Here's a blast from my past: a piezo-electric

hydrophone. This was my very first research gadget that I ever built. I put it

together roughly 10 years ago for my senior research project during either my

2nd or 3rd senior year of undergrad.

The goal was to listen to predatory whelks feeding on mussels in orderto estimate handling time. Because you can't really see the business end (the radula) of a whelk when it's feeding, the only good way to determine when a whelk is drilling is to listen for it.

Note the drill holes inthe Mytilus edulis shells around the Nucella lapillus shown above.

The hydrophone is based on a piezoelectric noisemaker, commonly found in things like home smoke detectors and Hannah Montana singing greeting cards (NB: It turns out that Hannah Montana greeting cards don't actually use this style of noisemaker).

When I was actually recording whelks drilling, I found that it helped to

use some 2-ton epoxy to glue one of the valves of the mussel directly to the

outer face of the plexiglass, right on top of the piezo unit. When a whelk

started drilling the mussel, this transmitted the drilling noise (more of a

scraping noise really) directly to the hydrophone, helping it stand out from

the background noise of water moving through the seawater system. This same

system could be glued to a rock to listen to the grazing sounds of herbivorous

gastropods. Just don't do anything lame like listen to whale songs. Study

something interesting that doesn't have a backbone!

The goal was to listen to predatory whelks feeding on mussels in orderto estimate handling time. Because you can't really see the business end (the radula) of a whelk when it's feeding, the only good way to determine when a whelk is drilling is to listen for it.

Note the drill holes inthe Mytilus edulis shells around the Nucella lapillus shown above.

The hydrophone is based on a piezoelectric noisemaker, commonly found in things like home smoke detectors and Hannah Montana singing greeting cards (NB: It turns out that Hannah Montana greeting cards don't actually use this style of noisemaker).

As sold, these

discs make a noise when you apply a voltage across the central ceramic disc and

the outer brass disc. But thanks to physics, you can do exactly the opposite as

well, produce a voltage across the ceramic disc and brass disc by making noise.

The hydrophone exploits this property of the piezoelectric noisemaker to turn it

into a microphone.

I can no longer

find the paper that I read that originally described this setup, but someone at

the Underwater Acoustics Group of the Loughborough University of Technology put

together this helpful pdf that describes the construction of the same unit:

A

cheap sensitive hydrophone for monitoring cetacean vocalisations.

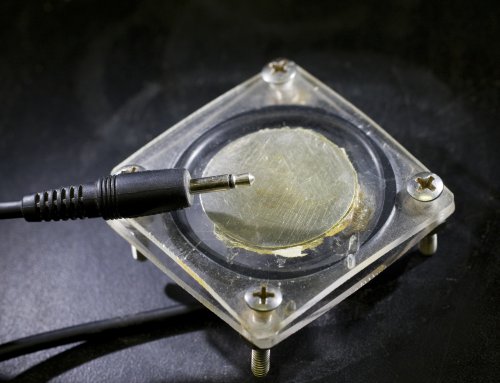

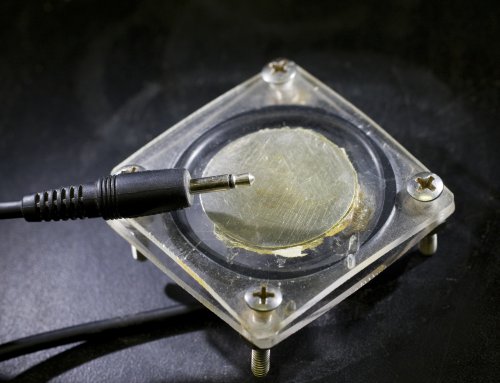

The hydrophone

essentially consists of one of these piezo noisemakers sandwiched between two

pieces of plexiglass, with an o-ring to provide the watertight seal and make

space for the wiring.

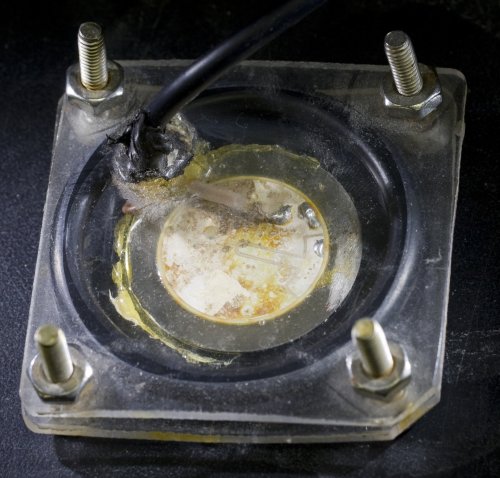

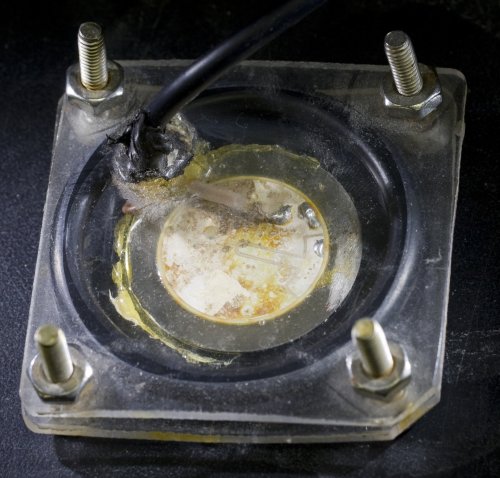

I used a long mono

headphone extension cord, as shown in the top picture, for my wiring. The mono

cord has two conductors in it. The central conductor gets soldered to the

ceramic central disc (visible in the picture above), while the outer conductor

gets soldered to the brass disc (not visible above, but see the pdf for a

diagram).

The wire is passed

through a drilled hole in one of the pieces of plexiglass, which is sealed up

with some sort of silicone caulk. 2-ton epoxy might be good here as an

alternative.

The other side of

the piezo disc then needs to be epoxied to the 2nd piece of plexiglass. This

provides a direct connection to the outside world so that sound is transmitted

efficiently from the water to the disc. Spread some 2-ton epoxy between the disc

and the plexiglass, and let it cure.

The two pieces of

plexiglass then get sandwiched together with a thick o-ring (something like

McMaster-Carrpart number 2418T197)

between them to keep water out. The bolts in each corner need to be tight enough

to slightly compress the o-ring. In my naive youth I just went ahead and cranked

things down until the plexiglass was ready to snap, but it always worked fine.

Once everything is

put together, you should be able to just plug your cord into the microphone

input of a computer and start recording sound. It may be necessary to crank up

the amplification quite a bit due to the very low level (low voltage) signal

coming from the hydrophone.

<< Home